Hello, and thanks for checking out this post on a Sprinter intermittent no start, no crank issue. The vehicle in question this time is a high-mileage Sprinter delivery route truck with a diesel engine. The problem cropped up with no apparent pattern, failing to crank at random times, and would often go some time with no problem. The starter and alternator had already been changed with no effect on the issue, and had been to the shop several times without success in replicating the problem. Finally, it was towed in after a complete failure.

Another mechanic started to look at the vehicle and was now able to reproduce the no crank several times. Oddly, when a no crank event happened, the electric A/C fan would run at key on, then nothing would happen when the key was further turned to start. I am always a little concerned about complaints of starting issues on Sprinters; if the first crank attempt fails to start the engine, the key has to be turned back off before trying to crank again. This seems to be common on foreign vehicles, and may trip some people up. However, the fleet that owns this Sprinter also has several others, so driver knowledge shouldn't be a problem. The starter relay is located behind the access panel under the driver seat. If you hold onto a starter relay and turn the key to start, you can feel the relay click when it energizes. That doesn't mean it is necessarily putting out power, but you know it has power and ground to energize it. This one was not clicking during a no crank, so the problem had to be between the key switch and the relay.

At this point the other tech’s shift ended and it was my turn to take a stab at the problem. With the knowledge of what part of the circuit to look at for the issue, I looked at the wiring diagrams the other tech had printed from Mitchell. I was looking at the wiring for some commonality between the starting circuit and the HVAC fan, when my shift manager came up with a diagram isolating the starting circuit. It was obvious that a couple of connections in that circuit were worth looking into. Particularly suspicious was a connection above the fuse block, and a splice joint below the seat. The engine control module itself was also worth thinking about.

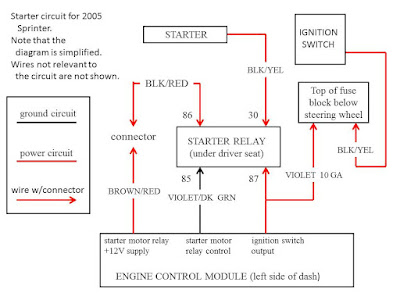

Below is a condensed version of the starting circuit. There are several things I find a little strange about how the circuit is wired. First, the starter relay gets power off the ignition switch itself. Normally a relay is powered from the battery so that reliable, high amperage power is available to the starter solenoid. The power from the switch signals the ECM to send ground to the starter relay to energize it. Also, the module pin marked starter motor relay +12V supply really isn't relay supply, but only power to energize the relay. It also energizes the fuel pump relay, which is not shown in my diagram. I understand that it is desirable to control the starter relay through the ECM, but the way this is wired, the starter solenoid is in reality getting its power directly from the 12GA wire from the ignition switch! The solenoid power also has to go through 4 connectors on its way to the starter. This seems to me to be a rather unreliable way to wire a starter circuit, as each of these connectors is a potential problem spot, especially as a vehicle ages. So much for the myth of fine German engineering.

Another mechanic started to look at the vehicle and was now able to reproduce the no crank several times. Oddly, when a no crank event happened, the electric A/C fan would run at key on, then nothing would happen when the key was further turned to start. I am always a little concerned about complaints of starting issues on Sprinters; if the first crank attempt fails to start the engine, the key has to be turned back off before trying to crank again. This seems to be common on foreign vehicles, and may trip some people up. However, the fleet that owns this Sprinter also has several others, so driver knowledge shouldn't be a problem. The starter relay is located behind the access panel under the driver seat. If you hold onto a starter relay and turn the key to start, you can feel the relay click when it energizes. That doesn't mean it is necessarily putting out power, but you know it has power and ground to energize it. This one was not clicking during a no crank, so the problem had to be between the key switch and the relay.

At this point the other tech’s shift ended and it was my turn to take a stab at the problem. With the knowledge of what part of the circuit to look at for the issue, I looked at the wiring diagrams the other tech had printed from Mitchell. I was looking at the wiring for some commonality between the starting circuit and the HVAC fan, when my shift manager came up with a diagram isolating the starting circuit. It was obvious that a couple of connections in that circuit were worth looking into. Particularly suspicious was a connection above the fuse block, and a splice joint below the seat. The engine control module itself was also worth thinking about.

Below is a condensed version of the starting circuit. There are several things I find a little strange about how the circuit is wired. First, the starter relay gets power off the ignition switch itself. Normally a relay is powered from the battery so that reliable, high amperage power is available to the starter solenoid. The power from the switch signals the ECM to send ground to the starter relay to energize it. Also, the module pin marked starter motor relay +12V supply really isn't relay supply, but only power to energize the relay. It also energizes the fuel pump relay, which is not shown in my diagram. I understand that it is desirable to control the starter relay through the ECM, but the way this is wired, the starter solenoid is in reality getting its power directly from the 12GA wire from the ignition switch! The solenoid power also has to go through 4 connectors on its way to the starter. This seems to me to be a rather unreliable way to wire a starter circuit, as each of these connectors is a potential problem spot, especially as a vehicle ages. So much for the myth of fine German engineering.

|

| 2005 Sprinter starter circuit |

Anyway, the fuse block under the steering column is easy to remove, so this seemed like a good place to start. Dropping the fuse block from the column caused the no crank issue to reappear, so it seemed as if one of the connectors there was at fault. The 12GA black/yellow wire from the switch goes to a connector at the right side of the block, and it re-emerges at another connector on the left side of the block as a 10GA violet wire. I jumped a wire between the two and the vehicle started. There is probably a fusible link across the top of the fuse block to protect the switch wire, but I had no desire to take the block apart and spend the next 2 hours chasing small parts across the shop just to find out. I cut the two wires off at their respective connectors and soldered them together, then bolted the fuse block back up.

I wanted to also check the starter relay under the driver seat to make sure its connector was sound. I grabbed the wires near the connector and pulled with about 10 pound of force, while trying the starter. The vehicle failed to start as long as I pulled on the wires. This is a sure sign that the connectors in the relay plug have lost their tension and can cause an intermittent fault. The OEM relay has 2 large spades that I didn't have a connector for, so I wired in a standard 5 blade relay with new terminals.

The last thing I wanted to check out was the splice in the violet wire the diagram said was under the driver seat, but it was not there. There is a fork in the harness under the vehicle, (under the seat area) so I assume that is where it is. I didn't break into that as it was in original condition, well-wrapped, and I didn't want to disturb it since I was pretty confident the problem had been solved.

It has been over a month since repair and the vehicle is driven daily, so it looks as if one or both of the things I did fixed the problem. As to why the HVAC fan ran when the truck failed to start, I haven’t really come to a conclusion as to the answer. It may be a quirk in the input/output circuits or programming of the ECM. One of these days we will replace a bad fuse block in one of these and I can blow it apart and check the guts, but one may want to insert a piece of fusible link wire between the wires I soldered together so the switch doesn't burn up in the event of a short or an overload in the starter circuit.

Thanks for checking out this post, and check back soon for more.

Bruce

7 comments:

The OEM relay has lager spades because it is rated for higher amperage. Usually a 70 amp relay. A common Bosch relay is rated for 30 amps.

Starter coils can draw large amounts of amperage when the batteries are low. This would not be a concern if the starter coil has its own relay on the side of it. Most common on gear reduction starters from Mitsubishi.

That illustrates one of the problems I have with the way the circuit is designed - providing power to the starter solenoid through a 70 amp relay, but via a mere 12GA wire directly from the ignition switch. Something has to give sooner or later.

Bruce

In no cranking condition with 2006 or later (normally with no glowplug light)I find its the 3 relays 6,7,8 in the LHS fusebox. They also seem responsible for the 'some keys work but others dont' problem. I suspect from what I have seen that its a mix of corroded contacts and how fast the relays operate. Strange but true.

Hi Bruce and all the other mechanics that have pulled their hair out with these sprinter issues. I bought a 2005 sprinter last year and the problem emerged with the starting issue about a month ago. I would hear a single click and then would not start. I would let it sit for five minutes and it still did the same thing. Then it would run my battery down and would have to get jumped. It always worked with a jump. After a while the jump no longer worked.

I have been with out my very loved sprinter. I'm a fine finish carpenter and travel up to 200 miles one way to install beautiful curved stair railings. I need a good reliable van with good fuel economy. I have the 2005 2500 158" wb. I love it!! My mechanic found that the clicking noise was the ECM detecting to much current to the starter. So the clicking sound is the ECM turning things off so things don't fry. Well my ECM fried 2 weeks ago and had to get it sent out, Reprogram a new one and replaced. I think the makers found this issue and put this code in the computer to help mechanics with this issue. I think this is very poor design. I can build something more reliable!! I had a Chevy Express for 7 yrs. Never once had this issue.

My mechanic has recreated the issue and found that the ECM was fried, then changed the starter. The problem disappeared. So, The clicking sound is a determination by the computer, one of many things, Starter relay?, Starter, bad grounding issues? Bad wiring?

But we all now know why Dodge divorced themselves from Mercedes.

I will keep my Sprinter now that my mechanic is well educated, via my purchase of my sprinter, lol.

Tim, Lancaster, PA.

Well I came across this post today after taking my Sprinter to several garages and they had no clue what was wrong. I was quoted thousands to have the van fixed and this included a new immobilizer and so on.

Although the problem was not exactly the same as yours, it did point me in the right direction, and in my case the fuse box underneath the steering column was not connected to the pins correctly. Without this post I would not have been able to known where to start to look for the initial problem.

Thank You :)

Thanks for the fuse block under the daSH CLUE. I HAVE THE "CLICK BUT NO CRANK" ISSUE ON A 2002 SPRINTER. HAVE HAD AN ONGOING fuse block issues under the steering column. hopefully i will post a success story fix in a day or so. the german engineers really haven't learned that complexity sometimes yields unexpected and bizarre results. they really need a good spanking. i know its to get around patents and keep their mechanics busy, but if i really wanted these kind of headaches i would buy a used porsche.

Re the above post by anonymous: Yes, one of the ways to really get me cranked up is to start talking about the excellence of German engineering.

I put a battery in an older sprinter today, and I couldn't believe that this thing actually used unique, dealer-only battery post ends. It used a group 72 battery that has pockets into which the posts are set. Due to limited accessibility of the battery position,the rear, negative battery clamp had a bolt to tighten it that was AT AN ANGLE to the clamp, so that there is clearance to get at the nut. The positive terminal has a small tab onto which is bolted the contact for a small fuse box. I have never seen anything like that before.

They could just as easily have used a 31P battery which is almost exactly the same size, and there would have been no problem getting at the battery clamps. Unfortunately you can't retrofit the group 31 battery, because the hold down would no longer work and there would be no easy way to clamp the battery to the existing battery tray.

At our shop we work on lots of Sprinters, and there are all kinds of issues similar to this. Examples? how about a lighting system that will set a check system light if a bulb with a slightly different current draw than the original, is installed. Or an oil level light so oversensitive that if you fill to the full mark in the shop, when the customer hits the road and the oil gets hot it indicates SLIGHTLY overfull and the oil overfull light sets. Or engine installations that make it easier to pull the engine for simple repair rather than doing it in the vehicle. Or needing 3 SEPARATE diagnostic programs to work on all years of Sprinter. I could go on and on, and I don't even work on the things much. Like I said, don't get me started.

Just for fun, go to an automotive job shop and announce that you have a Volkswagen that needs engine work. In moments every mechanic in the place will have gone into hiding and won't be found until the coast is clear.

Post a Comment